BELIEF

Color policy

Our colors

We have continuously prpmoted technical innovations in the dyeing for denim based on Japanese traditional indigo dyeing ("AI-ZOME")Technology.It is the wish of all the SAKAMOTO stuff to concentrate harder to come up to our customers expectations while making dramatic progress toward a bright future.

Unique dyeing technology

We have developed our own dyeing technology and dyeing machine which allows us to dye the yarn dark with the core white.

Eco action

We are located in the place with abundant water resources.We have been keeping good environment situation with continuous our own activities many years.

TRADITION

1800

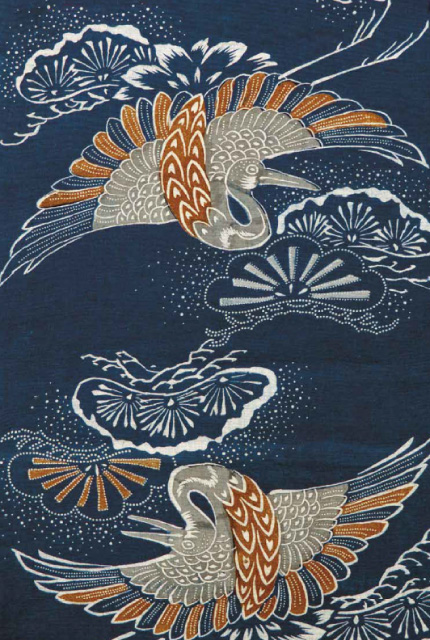

Japanese Traditional Indigo dyeing

It is said that Indigo is one of the oldest mankind dye stuff, and they were used all over the world. Natural Indigo is called “Ai” in Japanese. They were introduced to Japan from China 1500 years ago. They were distributed to the common people in the Edo period about 300years ago (1720s) and used for familiar materials such as clothes and bedding.

1892

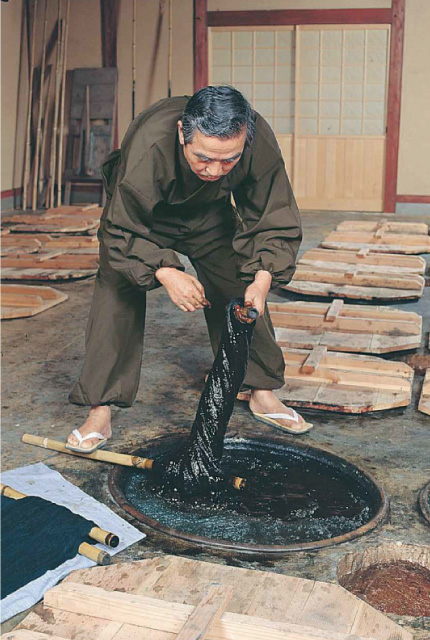

Unique hand dyeing style in Japan

First, the craftsmen ferment the Indigo ingredients for about a week. Then, in the Indigo liquor, they dye and adjust the yarn and fabric and dye it again over several days. This is Japan's unique Indigo dyeing technique that has been continued since the Edo period.

1967

The world’s first slasher dyeing machine

SAKAMOTO DENIM completed the first sheet-type continuous dyeing machine in the world that could dye the core of yarn white with Indigo. And it became possible to dye yarn with Indigo in large quantities with low cost and high quality and opened the way to be able to compete with the denim made in USA. In 1977, they also developed their own original rope dyeing machine.

2000 ~

The world’s first Eco-friendly Indigo dyeing system

SAKAMOTO DENIM has developed the most unique Eco-friendly dyeing system in the world.

Organic cotton cultivation in our place.

Realize a “self-reliant” food recycling loop by gathering kitchen garbage from each employee's home. They also changed their own boiler system efficiently comparing with previous one and also developed their own eco-friendly Indigo dyeing technology that made such efforts as reducing energy consumption and chemicals like washing materials. In 2010, the fourth generation Sakamoto developed such an environmentally friendly dyeing method because he was concerned about using a large amount of chemicals for dyeing processing even on organic cotton yarn.